What does temperature gradient stands for?

In physics, the gradient is a vector that indicates how a physical value vary in a volume.

The gradient is used to measure the variation in all directions of a given parameter.

At ATC, the most often used technical parameters are:

The gradient is used to measure the variation in all directions of a given parameter.

At ATC, the most often used technical parameters are:

- air velocity (m/s)

- air temperature (°C)

What are the interests and for which applications?

In specific applications such as laboratories or climatic cells, ATC is required to guarantee the same temperature at all points in a room. It means not to have any temperature gradient between the floor and the ground.

In tempered logistics such as perishable goods storage (chocolate, medics, vaccines), there is a real need to limit the temperature differences such as maintaining a gradient of 2°C between 0m and 18m height. The interest is the temperature homogeneity.

For example, when we deal with chocolate, we can guarantee that the products (located at 18m height) will not melt due to the stratification.

What is stratification? This is the accumulation of air layers of different temperatures over the height of a building. Warm air has a natural tendency to rise, resulting in a (sometimes significant) temperature difference between the top and the bottom of the building.

In tempered logistics such as perishable goods storage (chocolate, medics, vaccines), there is a real need to limit the temperature differences such as maintaining a gradient of 2°C between 0m and 18m height. The interest is the temperature homogeneity.

For example, when we deal with chocolate, we can guarantee that the products (located at 18m height) will not melt due to the stratification.

What is stratification? This is the accumulation of air layers of different temperatures over the height of a building. Warm air has a natural tendency to rise, resulting in a (sometimes significant) temperature difference between the top and the bottom of the building.

How does ATC manage to guarantee such result to its clients ?

Technical sales representatives and engineers collect physical and geometric data to design the aeraulic network such as:

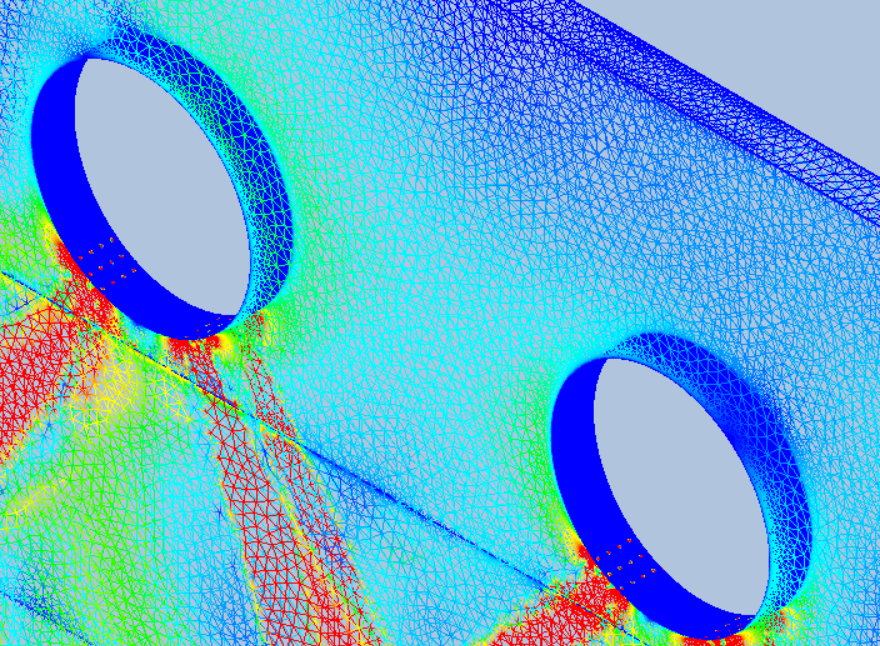

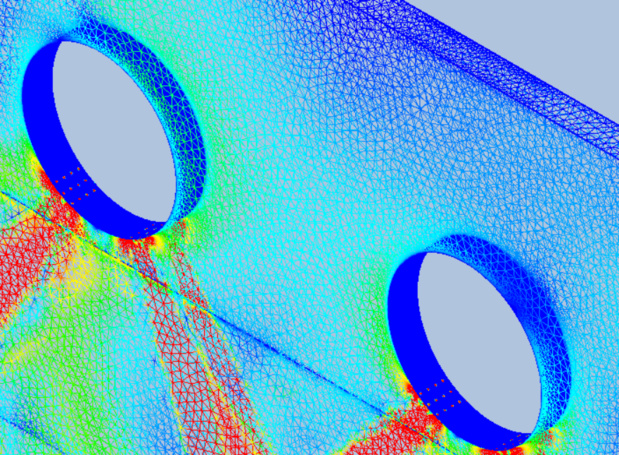

Induction rate and mixing rate calculations and in some cases numerical simulation of air flows will enable ATC to meet the requirements of industrial and logistic premises.

Moreover, for an air diffusers manufacturer, the guarantee of the final aeraulic result is a prerequisite for the durability of his activity.

You should pay special attention when designing a logistics or storage building. Indeed, the choice of ventilation and air conditioning that you put in your warehouse is decided in direct relation to the type of activity that your site hosts.

If you are the owner or lessor of a storage facility, you should try to define your best short and medium term needs, in order to anticipate the possible future changes that will take place in your warehouses.

- The room dimensions

- The position and the height of the ducts

- The air flow

- The operating temperatures (supply and room)

- The air intake (extraction)

- The air treatment goal

Induction rate and mixing rate calculations and in some cases numerical simulation of air flows will enable ATC to meet the requirements of industrial and logistic premises.

Moreover, for an air diffusers manufacturer, the guarantee of the final aeraulic result is a prerequisite for the durability of his activity.

You should pay special attention when designing a logistics or storage building. Indeed, the choice of ventilation and air conditioning that you put in your warehouse is decided in direct relation to the type of activity that your site hosts.

If you are the owner or lessor of a storage facility, you should try to define your best short and medium term needs, in order to anticipate the possible future changes that will take place in your warehouses.

Do you need any technical support?

Contact our team at the following address: atcinfo@aerotextile.mx

Contact our team at the following address: atcinfo@aerotextile.mx