From which data will ATC engineers size the features of a fabric duct network?

What is the thermal treatment type? (Refrigeration, heating, ventilation, reversible air conditioning)

A temperate logistics platform must not be treated the same way as a storage building in which fost-free conditions are required. Room temperatures, blowing temperatures and temperature gradient over the height of the volume are compulsory in the design of an air distribution and diffusion network.

What is the unit type? (Roof top / AHU / Ductable unit / Air heaters / Evaporator / Heat pump)

The selection of your unit, linked to the power (KW) and the pressure drops (Pa), is also key for the aeraulic network design. Indeed, they will determine the air flow rates (m3/h) to be blown and the pressures (Pa) necessary to calibrate the diffusing ducts.

What are the most frequent application constraints?

The most frequent application constraints are:

- The installation height superior to 10m

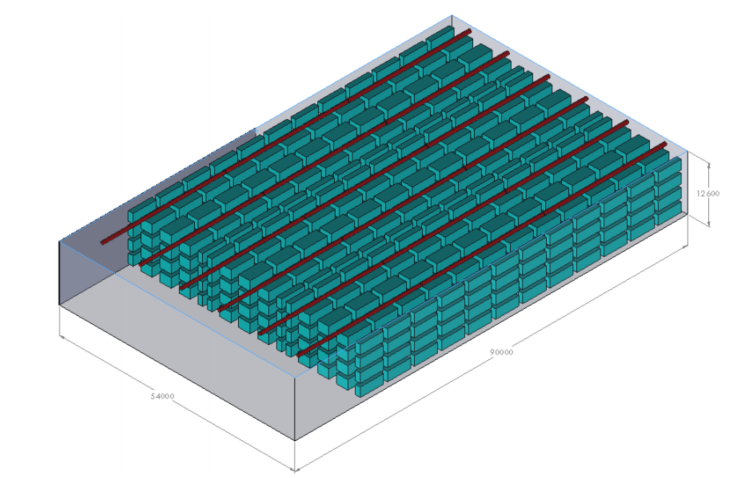

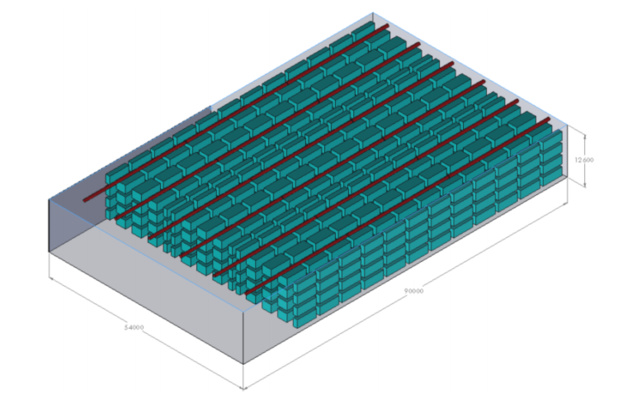

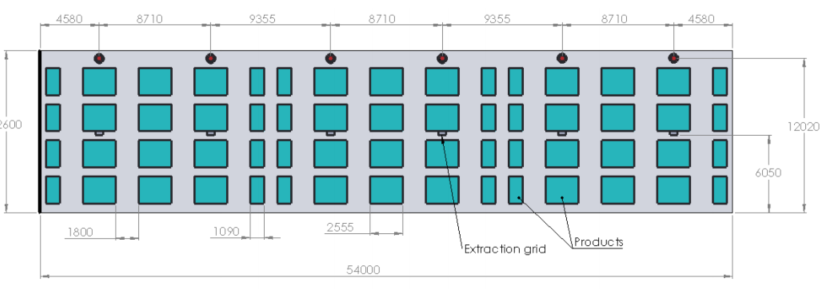

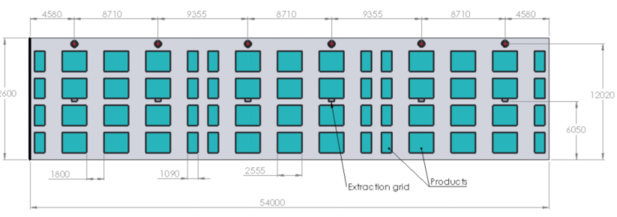

- The setup of the room

- The kind of foodstuff stored

- The diffusion obstacles (racks…)

- The room temperatures homogeneity

- ESFR standards for sprinklers (speed and bulk)

- Mastered air diffusion in specific areas / Zoning / Packaging

- The air extractions position

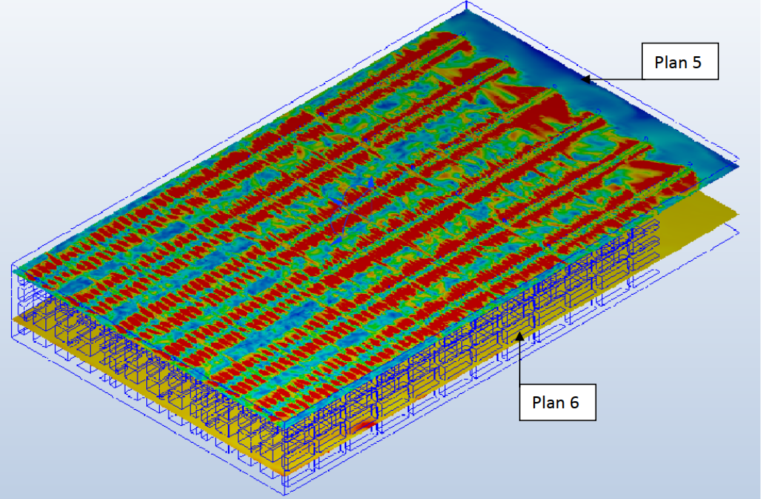

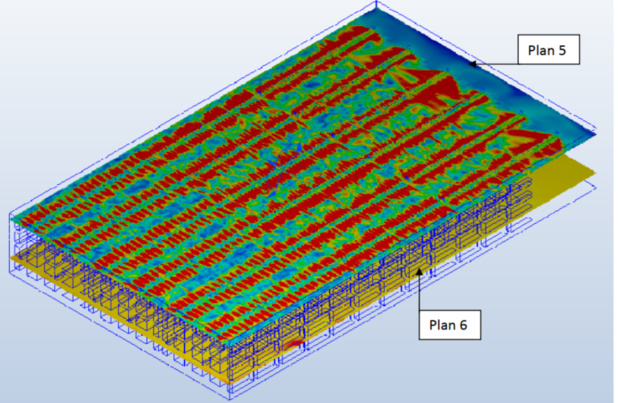

From all these inputs, ATC engineers will size the features of the fabric duct network. They will select the geometry of the ducts, the number of diffusers, the diffusion type (high or low induction). Thus, they will be able to calibrate a "tailor-made" air diffuser that meets the air treatment purposes.

For example, in logistics platform, maintaining a temperature of 20°C +/- 2°C over the height of the 6000 m² cell and 10 m height, all year long.

For example, in logistics platform, maintaining a temperature of 20°C +/- 2°C over the height of the 6000 m² cell and 10 m height, all year long.

What are the key data required to calibrate a fabric duct?

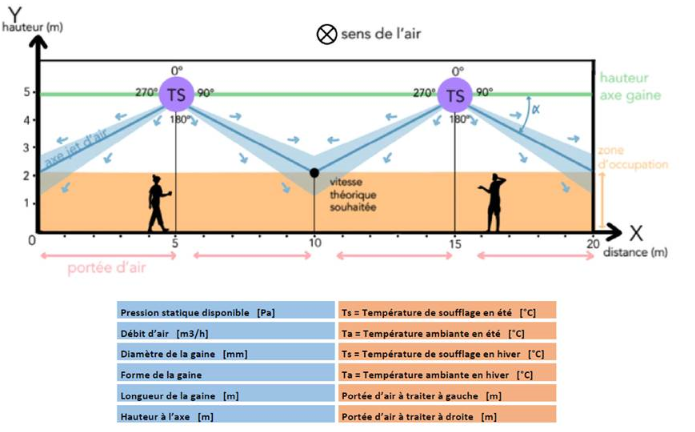

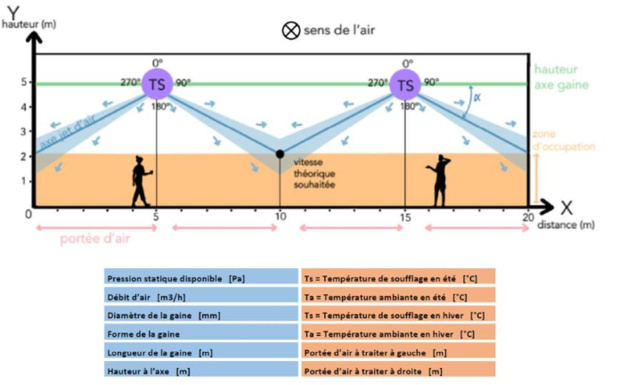

To size an Airneo air diffuser, we must gather technical and physical data.

In addition to the temperatures, we also take into account the height room, the air throw or the distance where we want bring the air. Then, we calculate the air velocity, the induction rate, the air stream deflection to guarantee the temperatures (°C), and velocities (m/s) in the desired areas.

In addition to the temperatures, we also take into account the height room, the air throw or the distance where we want bring the air. Then, we calculate the air velocity, the induction rate, the air stream deflection to guarantee the temperatures (°C), and velocities (m/s) in the desired areas.

In the context of the aeraulic air design, this is important to carry out your project with specialists who will be able to understand your problems and help you to solve them.

Do you need support to set up your fabric duct network?

Contact our technical team at the following address: atcinfo@aerotextile.mx

Do you need support to set up your fabric duct network?

Contact our technical team at the following address: atcinfo@aerotextile.mx